COOLING TOWER WATER TREATMENT PROCESS

May 3, 2022 at 4:02 PM

—

admin

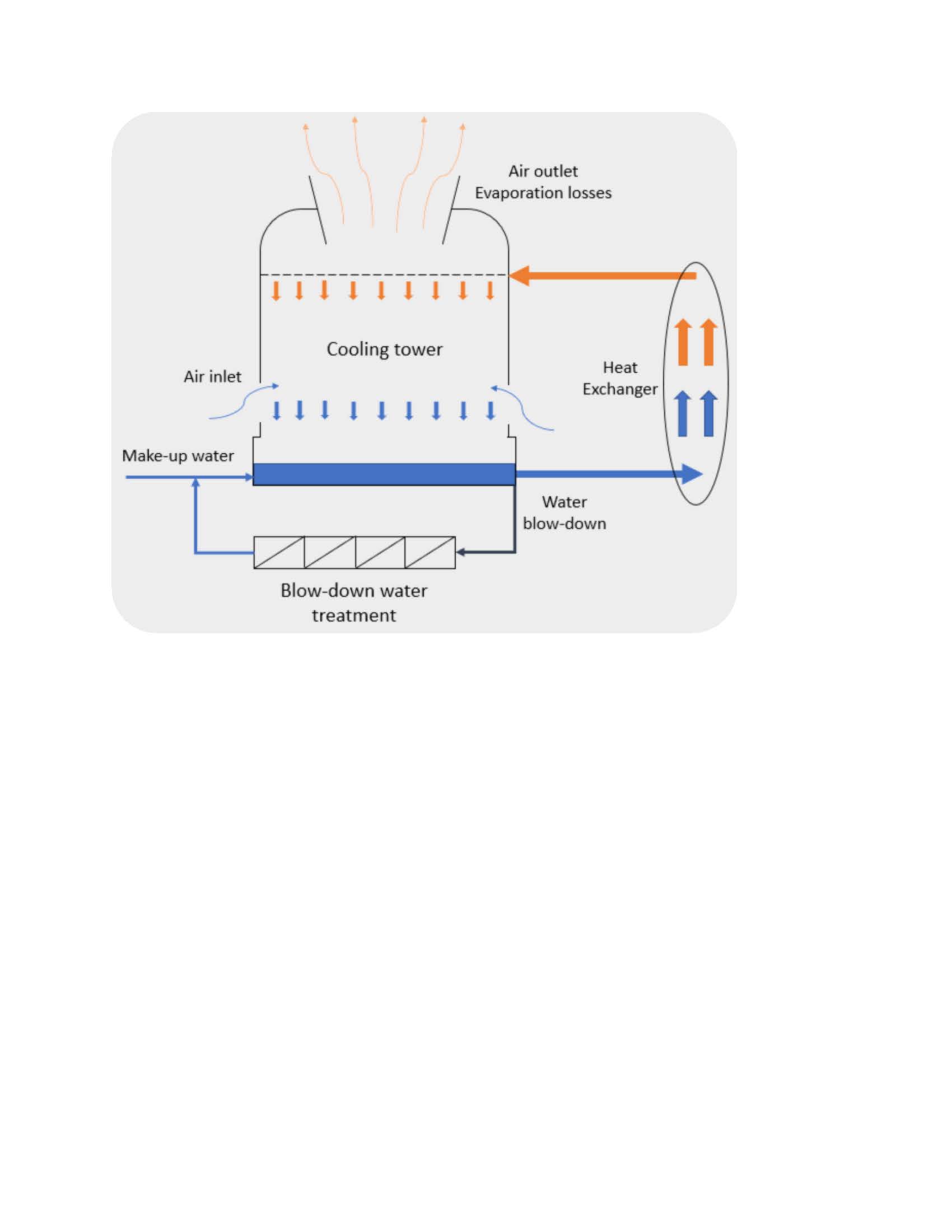

MAKE – UP water cooling tower blow town water treatment presents several challenges Due to the high salt concentrations and chemicals added in the cooling tower. Any water source has various levels of dissolved and suspended solids. Because the evaporative loss is water containing little to no solids, the water remaining in the cooling tower becomes concentrated. New water needs to be added to maintain the balance. However by equalizing the mass balance of water in the system, the amounts of dissolved solids will increase.

This can result in many problems in the cooling tower such as corrosion, scaling, fouling and micro biological growth. All these problems have an effect on performance and maintenance. In order to protect the efficiency and life expectancy of components, part of the concentrated water needs to be discharged. The purged water is called blow –down. Blow down water properties depend on pretreatment for makeup water and on number of cycles of concentration. Besides minerals (high TSS, TDS, Hardness and Alkalinity parameters), the water might also contain Algae, Bacteria.

To protect all these critical issues the process water to be pretreated. One the process water is pretreated, the blow down (or) concentrated process water can be reduced drastically. For pretreatment TIAANO’S ELECTROLYTIC SCALE REMOVER can be used. The attached image is self-explanatory.