Chemical Free Electrolytic Scale Remover in Natural Draft Cooling Towers

Natural draft cooling towers, also commonly called hyperbolic or hyperboloid towers are commonly used in thermal power plants, where the total heat extraction rate is at the level of several hundred MW.

In the Power Plants, the large condenser that create steam and run turbines. Other than that there are lot of other applications where water is used. The most common scale ingredient is CaCO3, or calcium carbonate in hard water. Here is the problem that, A large quantity of water are flowing through the Cooling towers Boilers, condensers, heat exchangers and other parts of a power plant, it causes the Scale deposit. All the Thermal power station, they face the similar problem.

It is very important to descale all these equipments, then only they can achieve the effective heat transfer, Moreover the formation of Scale can affect operations, leading to inefficiencies. The formation of scale, result in increased energy expenses and equipment failure.

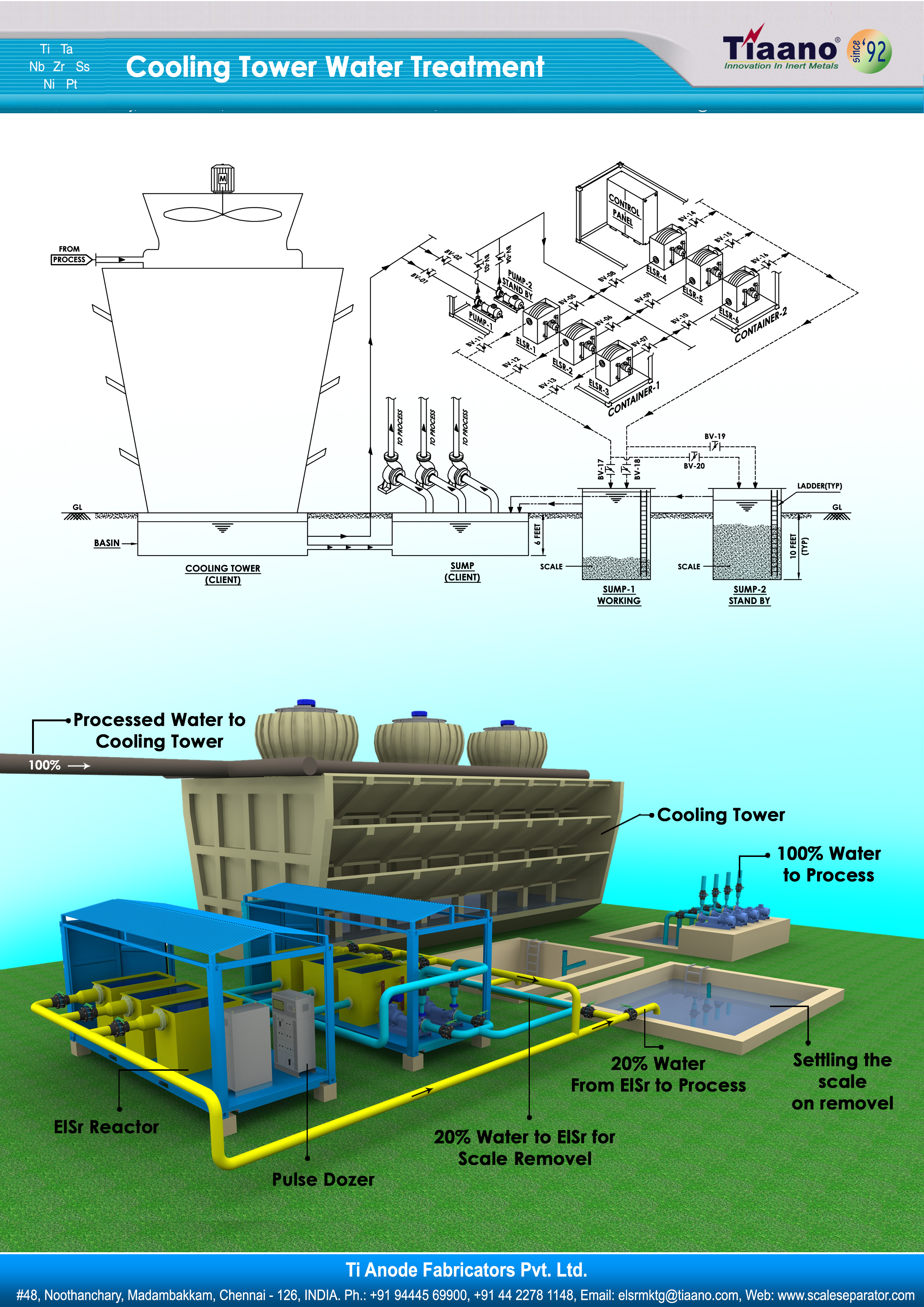

To overcome all these problems Tiaano introduced a technology to treat the water of natural Draft Cooling towers by Electrolytic Process.

Tiaano an ISO 9001 – 2007 & OHSAS 19001 – 2005 Certified company ventured and developed a Electrolytic Scale remover (ElSr), it removes the scale by Electrolytic operation without adding chemicals.( Zero Chemicals). It generates Oxidants in the water, oxidants miligate the corrosion, Bio – fouling, micro – organism growth, Scaling & spread of airborne bacteria.

Electrochemical technology:

Wherein ElSr attains the chemical decomposition by electrical current. The treatment system to provide controlled electrolysis in a reaction chamber to…

• Prevent scale precipitation.

• Control the formation of bacteria.

• Control the algae and slime.

• Prevent legionella.

• Prevent the corrosion.

• Reduction in blow-down water quality.

Potential benefits of using Tiaano’s ElSr :

• 100% savings on chemicals.

• No need of Softeners.

• 60 to 70% savings on blow down water

• 10 to 50% savings on labour cost,

• 20 to 30% of water savings,

• 05 to 15% of energy savings of cooling fan,

• 02 to 30% energy savings on Cooling Energy,

• 02 to 20% Saving on Boiler Energy in Power Plants.

• Increasing COC.

Scales Ionized by ElSr:

CaCO3 : Calcium Carbonate as Alkalinity

CaCO3 : Calcium Carbonate as Hardness

Ca : Calcium hardness

Mg : Magnesium

Na : Sodium

K : Potassium

No3 : Nitrate

Cl : Chlorine

F : Fluorine

So4 : Sulphate

Si : Silica

Fe : Ferric

Al : Aluminum

Cu : Copper

S : Sulphur

Anti-corrosion:

Galvanized tubes, stainless steel tubes, high-carbon tubes (used in the molding process), brass, red copper (used in condensers, heat exchangers and so on), hard aluminum (used in the process of molding), and stainless steel (used in condensers, heating tubes and so on) are widely used in circulating water systems. The main types of corrosions of materials mentioned above are as follows:

■ Aerobic Corrosion

■ Chloride Ions Corrosion

■ Under-deposit Corrosion

■ Electrochemical Corrosion

The problem of above kinds of corrosion can be solved by Tiaano ElSr (Anti-corrosion rate>95%).